COB, IMD, MIP

At present, Mini LED packaging has been formed, including COB (Chip on Board) technology and IMD (Integrated Mounted Devices) collection packaging technology,

MIP (Micro LED in Package) three kinds of programs. Next will be detailed description of the various types of technology.

Technical aspects

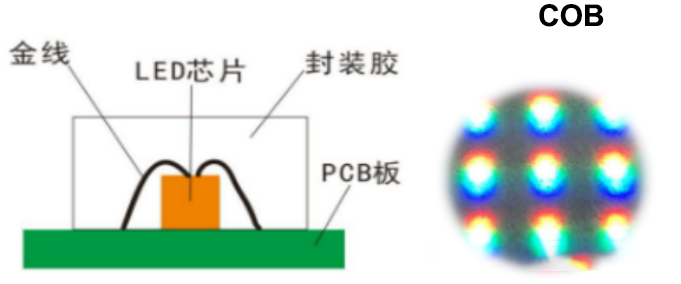

COB is a kind of multi-bead integration without stent packaging technology, directly the light-emitting chip encapsulated in the PCB board, eliminating the cumbersome table paste process,

without the stent welding feet, each pixel of the LED chip and welding wires are epoxy resin gel tightly and tightly encapsulated in the gel, there is no any exposed elements,

more like a surface light source, the overall nature and the protection of the better.

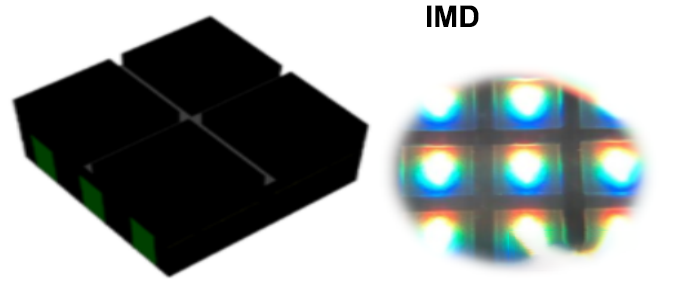

IMD (Integrated Matrix Devices) matrix integrated packaging solutions (also known as "N in 1" or "all-in-one"), the typical way to 2 * 2 form, that is, 4 in 1,

integrated package 12 RGB three-color LED chips.

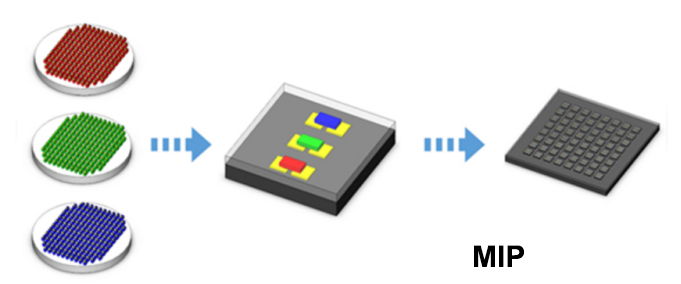

MIP is a new type of packaging architecture based on Micro LED, which is born out of the long-experienced small pitch display products, the essence of Micro LED and

discrete devices organic combination, that is, the large area of the whole display panel separate packaging, so that the smaller area under its yield control will be greatly improved,

while the test link from the chip to the packaging section, will effectively reduce costs to improve the rate.

In the process of development towards the era of micro-pitch display, SMD packaging mode has been difficult to break through smaller point pitch, it is also difficult to ensure

high reliability and protection, the industry needs COB, IMD, MIP and other technology routes to relay, coupled with the full-flip-loading process, the use of a huge amount of transfer methods,

can effectively reduce the point pitch.

Since 2016, COB packaging has attracted attention since the beginning of the study of Mini LED, Micro LED technology development and combined with COB encapsulation technology process,

with the continuous maturation of the process technology, PCB ink color consistency and optical consistency has been continuously improved, has included two series of products of

front-loading COB and flip-flop COB, compared with the IMD products, the advantages of COB encapsulation include Low power, good heat dissipation and high color saturation.

In 2021, Flip COB has already touched the 0.4mm Mini LED layer, and with the continuous innovation of technology, the COB industry will continue to move towards Micro LED.

In 2018, with the emergence of IMD packaging, the industry seems to have found a temporary alternative and a way to maximize the retention of the industrial supply chain,

IMD packaging equipment is more than 80% compatible, and after three years of development, the micro-pitch products of IMD packaging can be 0.9mm,

and due to the technological limitations of the SMT, it is basically difficult to achieve mass production of the products of the following P0.7mm pitch, and as the key micro-miniaturization,

the comprehensive cost of the product rises.

IMD can be viewed as a small COB unit, and the technical challenges faced are similar to those of COB packaging, with a reduction in difficulty, but there are certain physical limits to

the IMD solution, which cannot infinitely reduce the pixel pitch.

In general, the technical difficulties in the continuous breakthrough, micro spacing LED display industry is working hard to achieve the technical goals of Micro LED,

whether it is COB technology or IMD technology, the key to each technical route is to quickly reduce the cost and industrialization, with the outbreak of the market of small spacing,

the market demand for high-density high-definition enhancement, COB encapsulation and IMD encapsulation of the two different technical routes of the packaging Form also began to

compete on the same stage, the results need to be tested by the market.

Market development

In 2022, in order to better develop Micro LED, Nationstar launched a new MIP (Micro LED in Package) packaging device program. The new MIP packaging device program is

based on the fan-out packaging technology idea, Nationstar through the self-developed method of huge amount of transfer, the use of blackened substrate and

high light extraction packaging route to construct a new MIP device, greatly improving the device The optoelectronic performance of the device is greatly improved,

and the pin electrode is enlarged to match the current equipment, which has the advantages of low cost, high brightness, low power consumption, strong compatibility,

and can be mixed with BIN to improve the consistency of the display.

Nationstar introduction, MIP display module consistency is high, black ratio of more than 99%, with special optical design, horizontal viewing angle ≥ 174 °, strong compatibility,

compatible with the current equipment machine, can complete the test sorting, easy to detect the repair, easier to apply Micro LED in the terminal market.

MIP technology in the package scale adheres to a basic structure including a complete pixel, MIP is a typical independent lamp bead package, compatible with the downstream table

sticker production process, which makes the MIP in the test, repair, process fault tolerance is more flexible, the downstream is also due to the use of the table sticker traditional process,

as well as a single specification of the MIP will be able to meet the characteristics of multi-specification end-products, become more flexible.

With MIP and COB competing together, the "compromise" technology solution, IMD, may be the first to be marginalized or exit the stage of history. However, beyond the consensus,

the industry's perception of MIP and COB technology is still not small.

After years of development of COB technology, COB industry has established a mature and reliable common to the system, and the market scale continues to expand,

the earliest batch of COB large screen has been applied for more than 5 years, the effect and reliability of the performance of a wide range of confirmed and tested,

COB as a high-end technology solutions, has been deeply rooted in people's hearts, and has become a benchmark for the selection of high-end market.

The core advantage of MIP packaging is flexibility, terminal enterprises, especially not master COB technology did not enter the chip-level packaging process market terminal brand,

will be an excellent path to enter the micro-pitch LED market, more middle and lower brands will enter the micro-pitch LED display market through the MIP, may bring the "cottage effect ",

uneven terminal quality will be the image of MIP technology is not yet known, but MIP packaging technology with its production organization flexibility, is not the formation of real

market competitiveness, there is still a huge suspense.

Summarize

MIP's greater significance is to replace IMD and SMD in the small pitch and micro-pitch, rather than competing with COB, the future may form COB and MIP high and low with the situation,

through the current market situation, continue to do a good job of COB, accept the MIP is a choice of the current market, in the long run, COB and MIP cooperation will be greater than

the competition, must be adhered to and continue to invest in the enhancement of, the future will eventually what technology will rule the micro-pitch display.

Which technology will ultimately rule the future micro-pitch display, but also need time to test.

Bldg 8, Jinan Road, GuangMing District,Shenzhen,China

Bldg 8, Jinan Road, GuangMing District,Shenzhen,China E-mail:sales@protemled.com

E-mail:sales@protemled.com Tel: +86-755-36614049

Tel: +86-755-36614049